Introduction

In the realm of modern manufacturing and design, laser engraving stands out as a revolutionary technology. It offers unparalleled precision, versatility, and speed in engraving a wide range of materials. But what exactly is laser engraving, and how does it work? This article delves into the world of laser engraving, exploring its mechanisms, applications, and benefits.

What is Laser Engraving?

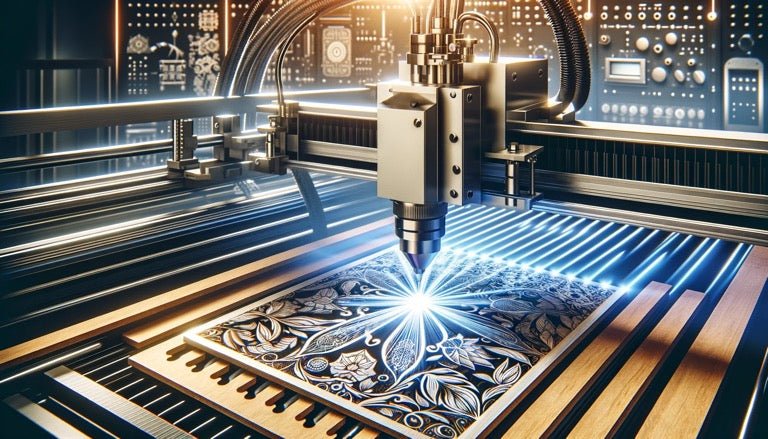

Laser engraving is a technique that uses laser beams to engrave an object. The process involves using a laser - a focused beam of light - to mark or etch designs, text, or images onto various materials. Unlike traditional engraving methods, laser engraving is non-contact, meaning the tool does not physically touch the material, reducing wear and tear.

How Does It Work?

The process begins with a design, typically created in a computer-aided design (CAD) program. This design is then sent to the laser engraver. The laser beam, controlled by the computer, is directed onto the material’s surface, where it removes a layer of the material to create a visible mark. The intensity, speed, and spread of the laser beam can be precisely controlled, allowing for intricate and detailed designs.

Materials Suitable for Laser Engraving

Laser engraving can be used on a variety of materials, making it a versatile tool for many industries. Some of the common materials include:Introduction to Laser Engraving Technology

Laser engraving, a cutting-edge technology in the manufacturing industry, has revolutionized the way we create detailed and personalized items. This guide delves into what laser engraving is, its mechanisms, and its diverse applications, highlighting its role in modern manufacturing.

What is Laser Engraving?

Laser engraving is a non-contact process that utilizes a focused beam of light - a laser - to etch designs onto various materials. Unlike traditional methods, laser engraving offers precision and versatility for customizing products ranging from industrial parts to personal gifts.

The Laser Engraving Process Explained

The journey of laser engraving begins with a digital design, often created in CAD software. This design is then sent to a laser engraving machine. The laser beam, meticulously controlled by the software, precisely removes material layers from the object, creating visible engravings with exceptional accuracy.

Versatile Materials for Laser Engraving

Laser engraving’s adaptability is evident in its compatibility with numerous materials:

• Metals like stainless steel and aluminum

• Woods of various kinds

• Plastics, including acrylic

• Glass and leather

• Papers and cardboards

Applications of Laser Engraving in Various Industries

1. Personalization: Crafting unique jewelry and bespoke gifts.

2. Industrial Marking: Adding serial numbers and barcodes to equipment.

3. Art and Design: Creating intricate artworks and decorative pieces.

4. Branding: Customizing promotional merchandise with company logos.

Benefits of Laser Engraving Technology

• Precision and Detail: Achieves high-level detail, even on small items.

• Efficient and Fast: Surpasses traditional engraving in speed.

• Versatile Uses: Suitable for a wide array of materials.

• Durability of Engravings: Produces long-lasting, fade-resistant marks.

• Eco-friendly: Minimizes waste and energy use.

Conclusion: The Future of Laser Engraving

Laser engraving stands as a beacon of innovation in modern manufacturing, offering efficiency and creative freedom. As technology evolves, the potential for laser engraving expands, promising new avenues for design and production.

In the realm of modern manufacturing and design, laser engraving stands out as a revolutionary technology. It offers unparalleled precision, versatility, and speed in engraving a wide range of materials. But what exactly is laser engraving, and how does it work? This article delves into the world of laser engraving, exploring its mechanisms, applications, and benefits.

What is Laser Engraving?

Laser engraving is a technique that uses laser beams to engrave an object. The process involves using a laser - a focused beam of light - to mark or etch designs, text, or images onto various materials. Unlike traditional engraving methods, laser engraving is non-contact, meaning the tool does not physically touch the material, reducing wear and tear.

How Does It Work?

The process begins with a design, typically created in a computer-aided design (CAD) program. This design is then sent to the laser engraver. The laser beam, controlled by the computer, is directed onto the material’s surface, where it removes a layer of the material to create a visible mark. The intensity, speed, and spread of the laser beam can be precisely controlled, allowing for intricate and detailed designs.

Materials Suitable for Laser Engraving

Laser engraving can be used on a variety of materials, making it a versatile tool for many industries. Some of the common materials include:Introduction to Laser Engraving Technology

Laser engraving, a cutting-edge technology in the manufacturing industry, has revolutionized the way we create detailed and personalized items. This guide delves into what laser engraving is, its mechanisms, and its diverse applications, highlighting its role in modern manufacturing.

What is Laser Engraving?

Laser engraving is a non-contact process that utilizes a focused beam of light - a laser - to etch designs onto various materials. Unlike traditional methods, laser engraving offers precision and versatility for customizing products ranging from industrial parts to personal gifts.

The Laser Engraving Process Explained

The journey of laser engraving begins with a digital design, often created in CAD software. This design is then sent to a laser engraving machine. The laser beam, meticulously controlled by the software, precisely removes material layers from the object, creating visible engravings with exceptional accuracy.

Versatile Materials for Laser Engraving

Laser engraving’s adaptability is evident in its compatibility with numerous materials:

• Metals like stainless steel and aluminum

• Woods of various kinds

• Plastics, including acrylic

• Glass and leather

• Papers and cardboards

Applications of Laser Engraving in Various Industries

1. Personalization: Crafting unique jewelry and bespoke gifts.

2. Industrial Marking: Adding serial numbers and barcodes to equipment.

3. Art and Design: Creating intricate artworks and decorative pieces.

4. Branding: Customizing promotional merchandise with company logos.

Benefits of Laser Engraving Technology

• Precision and Detail: Achieves high-level detail, even on small items.

• Efficient and Fast: Surpasses traditional engraving in speed.

• Versatile Uses: Suitable for a wide array of materials.

• Durability of Engravings: Produces long-lasting, fade-resistant marks.

• Eco-friendly: Minimizes waste and energy use.

Conclusion: The Future of Laser Engraving

Laser engraving stands as a beacon of innovation in modern manufacturing, offering efficiency and creative freedom. As technology evolves, the potential for laser engraving expands, promising new avenues for design and production.

Laissez un commentaire